NEXT GENERATION CLEANING PROCESS AT CENOVA

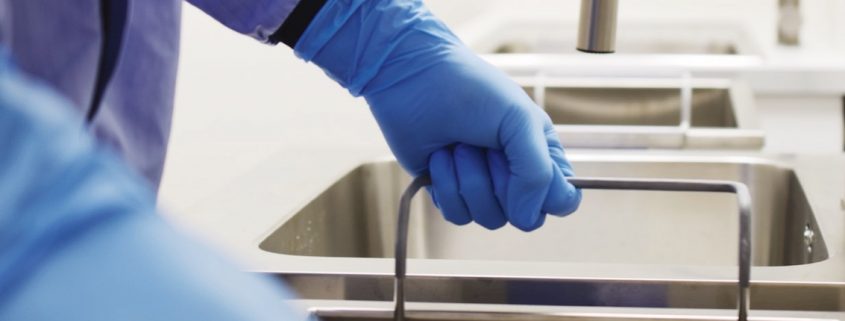

In order to expand their offerings and offer a cleaning process that meet high regulatory demands, Cenova has invested both in new infrastructure, including new clean rooms, and in new equipment such as several new ultrasonic cleaners. Some of these are placed in an unclassified environment for pre-cleaning steps and rinsing of sourced components. The components are then transported through an airlock system to a clean room environment for additional cleaning steps, rinsing and drying. In order to have control over the whole process the investment also includes equipment to produce purified water.

“We want to secure the whole chain and all the aspects that may impact the level of cleanliness on the end products. By producing our own water and having control of the process, we will reduce the risk for unknown process variations. Variations that in the end may impact not only sterility but also product functions, such as adhesion in our gluing processes,” says Johannes Kask, quality manager at Cenova.